Great schools, completing great projects – Unity College

Written by Kevin Visser- Teaching and Learning Leader Industrial Technology & Design

Unity college students are now well and truly on their way to successfully being the first school to CNC cut and fabricate their very own 4.8 meter boat. Since the last update, our engineering skills students have almost completed the forming of the main hull. This was a great experience for all students involved, and forced them to find innovative ways to manipulate and shape the flat sheets into the curved hull that you see today. In the lead up to this project, students had the opportunity to practice their aluminium welding. They were able to use augmented reality welding simulators, Thanks to TAFE Queensland. They then spent many hours welding scrap material. These practice Welds then became part of the students assessment. Students are now testing themselves by completing all of the structural welds on the actual boat.

This has allowed them to experience first-hand the difficulty in transitioning from bench Welding, to welding inside an actual hull, and often in awkward positions. Many students rose to the challenge with the results speaking for themselves.

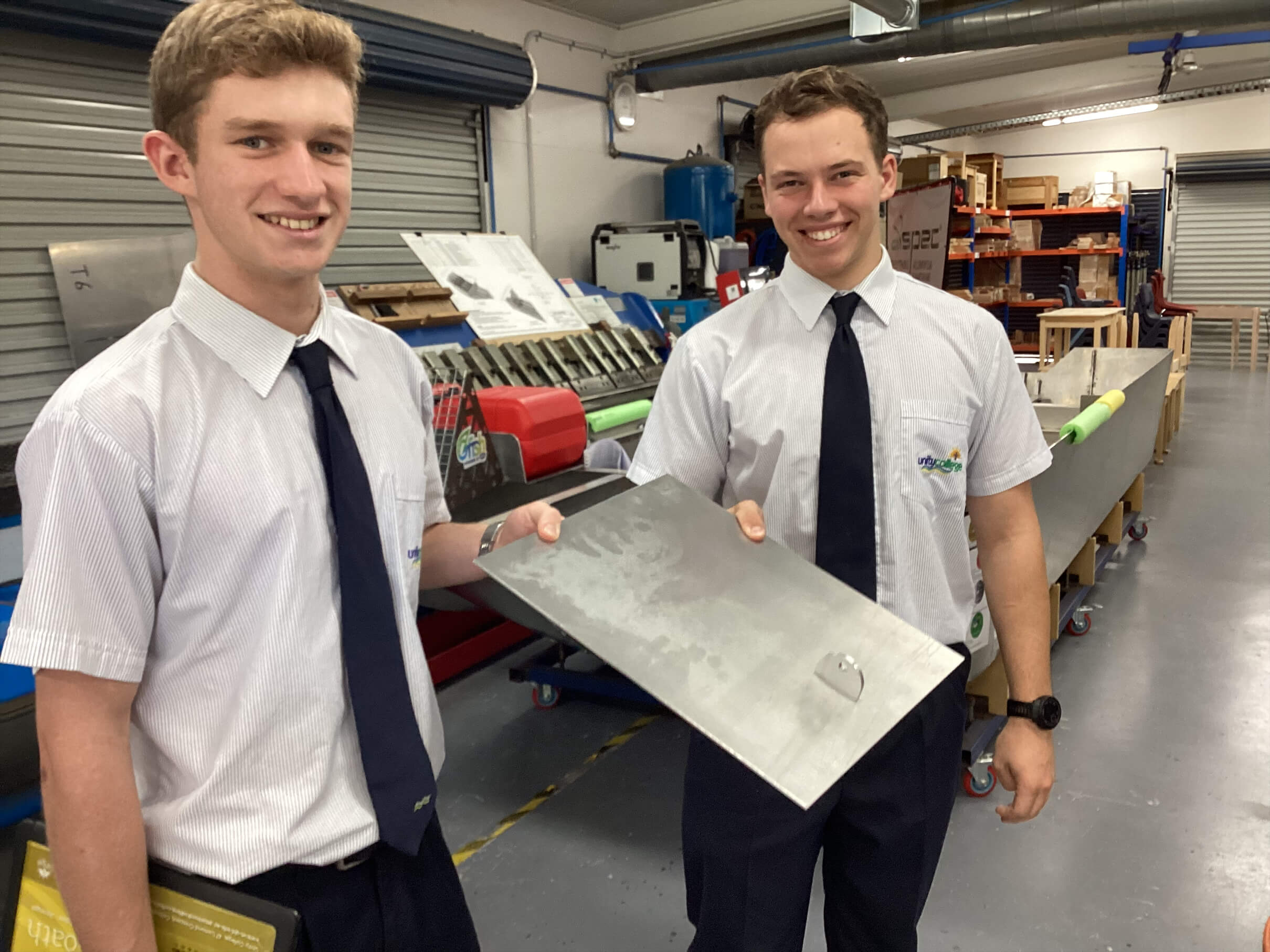

Unity College has been working alongside of the CNC Marine’s naval architects in the design of this boat. Intentionally, multiple features of the boat where not included in the original Naval architects design. This was so our certificate three engineering technical students could lead the way in custom designing these compartments and components. These included, fuel cell holders, anchor Wells, bilge pump and battery mounting brackets. All of the parts started as design concept sketches, then were transformed and tested as 3-D CAD models.

From here they were either Laser cut from MDF or 3D printed so students could directly test, evaluate and refine the parts. Students, then programmed our very own CNC router to cut the parts from marine grade aluminium sheet. These parts were then given to the engineering skills fabrication team for fitting to the vessel.

From here they were either Laser cut from MDF or 3D printed so students could directly test, evaluate and refine the parts. Students, then programmed our very own CNC router to cut the parts from marine grade aluminium sheet. These parts were then given to the engineering skills fabrication team for fitting to the vessel.

Unity College would love to thank Al spec Aluminium, CNC Marine and Gray’s Marine who have been amazing in supporting this community-based project.

If you’d like to know more about the earlier stages of the project, or the intended use for the vessel on completion, please check the description for links to other videos in relation to this project.