ALUMINIUM BOAT DESIGN

FEATURES

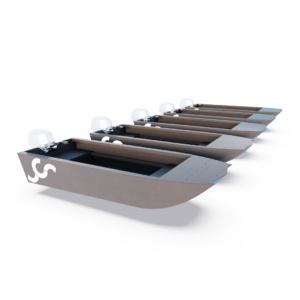

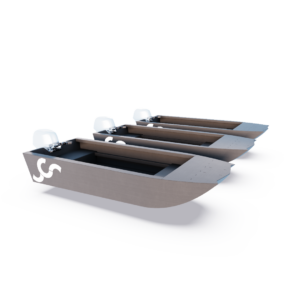

Unlock the power of precision with our revolutionary 3D aluminium boat kits. Crafted with cutting-edge 3D CAD software, our kits are meticulously constructed in the virtual realm before they come to life.

ALUMINIUM KIT BOATS

WHY CNC MARINE

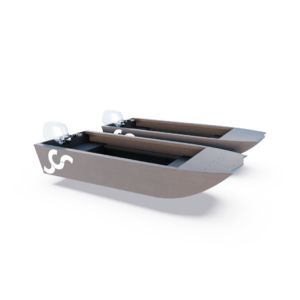

HULL SHAPE DESIGN

Using advanced naval architecture software, we design 3D aluminium boat kits from scratch. With unique hull shapes to best suit the conditions off the Australian coast, a variable deadrise combined with an inverted forward chine for a balance between stability at rest, you will enjoy smooth water planing and rough water comfort. The inverted chine allows for a finer entry to increase comfort levels when heading into choppy seas, and the flatter deadrise aft promotes stability and easy planing below the waterline. Once satisfied with the hull shape, we extract the individual plate shapes for computer-controlled cutting. Doing the trial and error on the computer, with the exception of our ‘Punts,’ keeps our design development costs to a minimum.

BOAT DESIGN PLANS BY QUALIFIED ENGINEERS

Aluminium is a great material for building boats since it is lightweight and corrosion-resistant. The downside is that it has very poor fatigue resistance. In areas of repeated vibrations, such as those caused by engines and sea chop, aluminium is more prone to cracking than steel and other materials. This is why it is vital that your boat design plans are made by qualified experts. When designed properly, the risk of cracking is significantly minimised. We place so much importance on CNC cutting to allow us to use stress-relieving shapes. Not only do we design the best shapes, we cut them cost effectively.

INDIVIDUAL FISHING BOAT DESIGNS

Designing small aluminium boats is extremely complicated. Their lightness makes them very sensitive to weight changes and subtle hull shape changes. An incorrect hull shape can make the chines sit too deep in the water, causing difficulty in getting on the plane, which increases running costs. If the hull shape is too full, the chines will sit out of the water, resulting in poor stability and handling. Finding the right balance of boat weight and hull shape takes time and skill. Look around and you will notice just how many small aluminium boats sit with their chines out of the water.

For this reason, each CNC Marine hull shape is specifically designed for the configuration offered. While it would be easier and cheaper to use the same hull shape, for example by extending it or swapping a walkaround cabin for a half cabin, the result would be inferior in performance and stability. The use of modern computer technology allows us to fine-tune each hull shape in a cost-effective way, to do the job properly.

ALUMINIUM BOAT DESIGN — BEYOND THE STANDARDS

Our aluminium boat design refers to Australian Standard 1799, BV rules for High Speed Light Craft, DNV rules for High Speed Light Craft and the USL Code. We then apply fundamental engineering principles in areas not covered by these rules such as stress-relieving cutouts. We go beyond simply meeting the minimum requirements.

SOLID FRAME CONSTRUCTION

To maximise the strength and safety of your boat, our hull frames are full depth solid plate. Unlike some manufacturers, we do not use floating frames. On CNC Marine boats each frame is welded to the bottom plate. The use of floating frames has no technical merit and is purely a cost saving measure. We only cut costs when it doesn’t cut quality.

CONTOURED STIFFENERS

Our software allows us to develop longitudinal stiffeners that are cut to the exact shape of the hull bottom and are oriented perpendicular to the bottom plate at all times. This reduces the chance of the stiffener “tripping” and losing its strength. They are stitch welded to the bottom plate using DNV welding guidelines, and are fully welded to each frame section. The cutout in the frame has a stress-relieving contour on top to minimise the possibility of cracking. Our stiffeners are cut from plate, which makes them 26% stronger than an extrusion. Some well known manufacturers only use standard flat bar extruded stiffeners that are not contoured and are not perpendicular to the plate, and therefore not as strong.

BUILT IN CHINES

We design our boats with chines that are built in the same way that larger commercial boats are built. The chine is inserted between the bottom and side plates and fully welded inside and outside. The alternative is to join the side and bottom plates directly, and then cap the join with an extruded angle section. We don’t design this way due to the risk of crevice corrosion. If this capped section should ever leak, damp salt would build up inside.

The area would then become oxygen deficient and corrosion would be accelerated. Some builders drill drainage holes in the ends of capped chines to let water out if it ever leaks. The problem is that this also lets the saltwater in. While the water would drain out, the salt would build up.

By building the chines our way, this problem is eliminated. The use of computer-controlled cutting allows us to build in this way without extra cost. We tend not to use reverse angled chines as we believe they increase running costs due to causing extra drag.

WELDING CONNECTIONS

Some builders use lap joints when joining frame halves and brackets. While this is acceptable in steel applications it is not good practice for aluminium. Classification societies do not allow lap joints in commercial vessels. We do not use lap joints anywhere.

We include welding diagrams as part of our instructions to you. We also etch the weld pattern lines directly to the kit plates so there is minimal chance of you getting the design of your DIY plate boat wrong.

CNC CUT

All plate parts for the boat are nested onto standard size plates and are cut using CNC-controlled cutters. This allows us to minimise material wastage and ensure that the parts are the correct size and shape. It also allows us to use shapes that would be difficult to cut by hand, such as our stress relieved stiffener cutout. It doesn’t cost any more to computer cut a simple shape or a complex shape, so we can design the structure with intricate stress-relieving shapes at no extra cost.

CURVED EDGE BRACKETS

We could dedicate a whole website to aluminium fatigue and how to avoid it. One important consideration is how stiffeners are bracketed. We only use brackets with curved edges that allow a smooth transition in stiffness. This minimises the risk of cracking the stiffener at the edge of the bracket. The use of this style of bracket is not common because it is easier to cut a straight-edge bracket using a guillotine rather than cutting a curved edge bracket with a hand saw. Our CNC cutters can cut superior curved brackets, again at no extra cost.

MARINE GRADE ALUMINIUM

We only use DNV (or equivalent) certified marine grade plate.

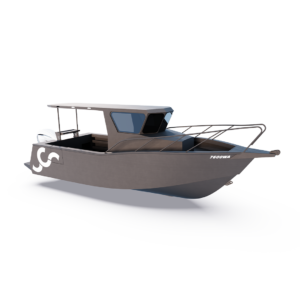

THE END RESULT

Using cutting-edge technology in the design process means that properly engineered boats can be built quickly and with minimal distortion from the original 3D boat plans. That includes all options, such as fishing boat designs and other bespoke models. Reduced residual stresses in the aluminium and reduces the risk of cracking problems. It also improves the look of the boat and reduces the costs associated with bogging before painting.

Completed CNC Boats by Profesional Builders