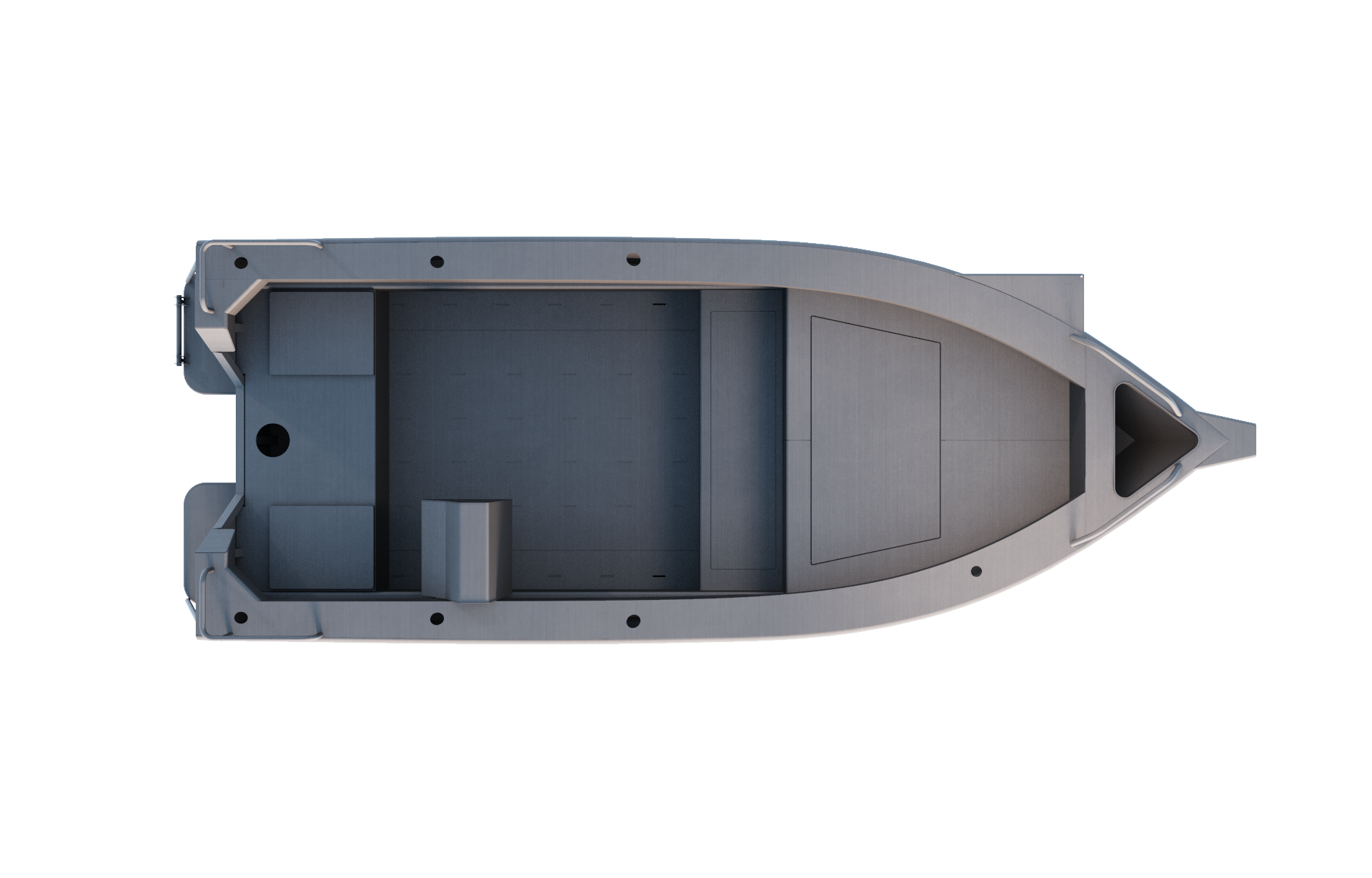

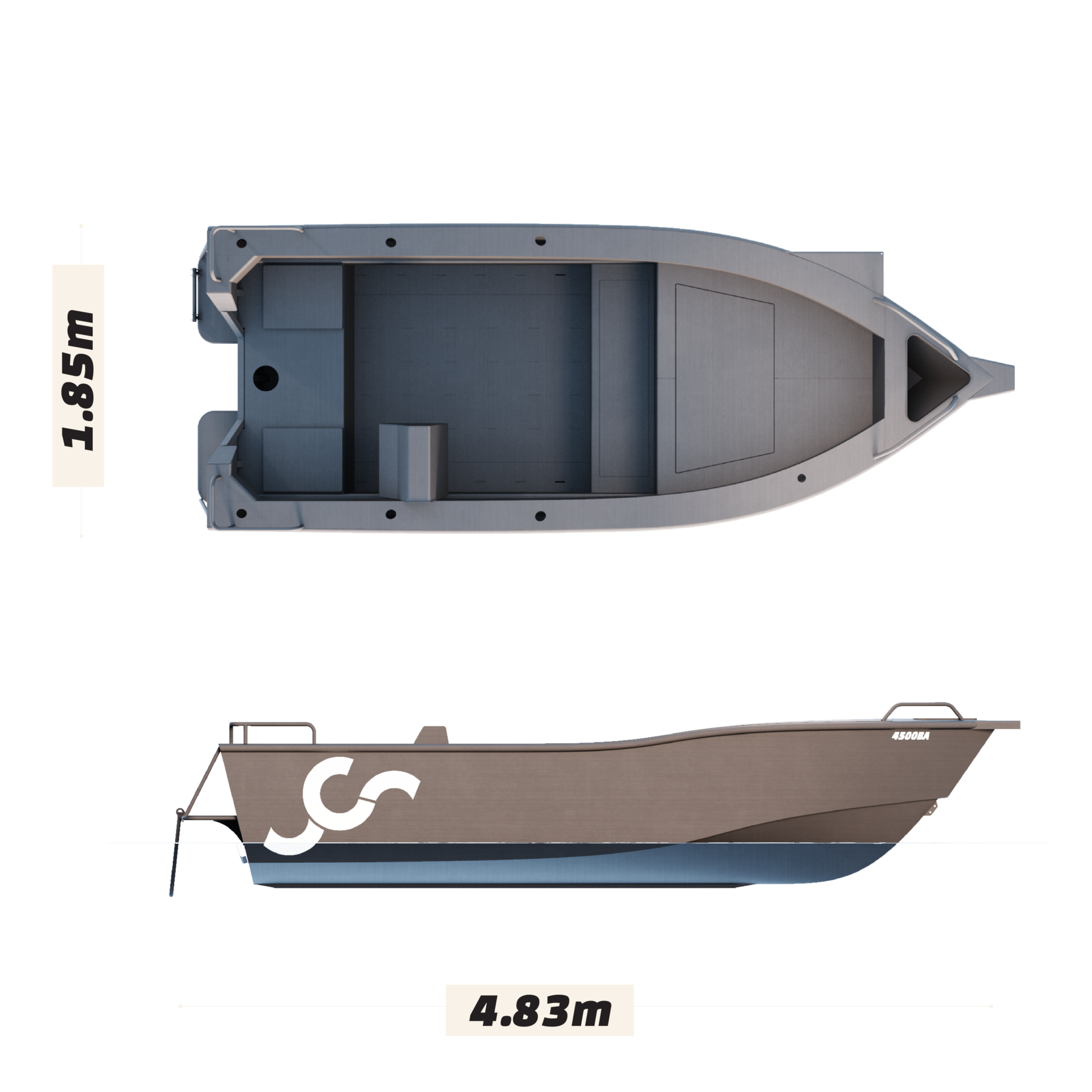

Specifications

CNC Length

4.5m (14.8ft)Overall Length

4.83m (15.84ft)Beam Width

1.85m (6.07ft)Overall Height

0.99m (3.25ft)Hotworks Weight

340kg (750lbs)Max Full Load Displacement

1158kg (2553lbs)Tow Weight

613kg (1352lbs) (Not Including Trailer or Gear)Mass of Boat and Fixed Fuel (Excluding Eng)

428kg (944lbs)Max Number of Persons

4pax - 360kg (794lbs)Max Engine

100HP - 185kg (408lbs)Presumed Design Engine

60HPEstimated Speed at Design Power

Leg Length

533mm (21in)Fuel Tank Capacity

80L (21.2gal)Aux Tank Capacity

n/aThickness

Bottom 3mm (1/8in), Sides 3mm (1/8in), Deck 3mm (1/8in )

Boat Kit Price

*All prices are in AUD + GST

Pricing excludes delivery. Please fill out the online form so we can send you an accurate quotation.

Personalise this vessel

We understand that owning a boat is a very personal experience, and we want to help make your boat uniquely yours. We offer the ability to personalise your vessel. Such as increasing fuel capacity, changing engine arrangements, adding or removing doors and hatches, and much more. To get started…

Step 1. Simply tell us what you have in mind, whether it’s a list of changes or sketches of your ideas.

Step 2. We’ll provide you with a fixed price quote that includes any estimated material costs. In the rare case that material costs increase, we reserve the right to charge you for any additional costs. Once you’re ready to proceed, you’ll pay a deposit to secure your place in our project pipeline.

Step 3. When your turn comes up, we’ll begin designing your personalized modifications. We’ll send you images and/or a 3D viewer file to review, and you can provide any minor changes needed. Once you’re satisfied with the design, we’ll create your personalised kit.

Step 4. Finally, you’ll receive your customised kit, just like any standard kit.

With our personalised services, you can make your boat truly one-of-a-kind.

Repeat Buyers Price

As a previous purchaser of this design, you would qualify for our repeat buyers’ price. This price is significantly lower than the original cost as it is based on current material and cutting at cost price, with an added handling fee. To receive an up-to-date price, please give us a call.

Kit Assembly Service

Do you want to have the boat built for you? We can arrange for a CNC Certified Boat Builder in your area to put the kit together for you. This can be to a finished hotworks stage ready for fitout.

CAD Cutting Files

Generally, purchasing kits offers greater cost-effectiveness and a wider range of advantages.

In some circumstances we are able to sell the 2D CAD Cutting Files. This also includes the PDF Construction Drawings and Calculations.

Rights of use of those files differ depending on the situation. This may include single use, minimal multi use, or unlimited use.

Order now

Order Now

Fully Refundable Deposit

Placing an order not only secures your position in the queue for kit delivery but also ensures your place in the modifications pipeline, if modifications are applied. Due today $1,000 + GST

Cancel Anytime

Priority availability

100% refundable

T&C’s apply

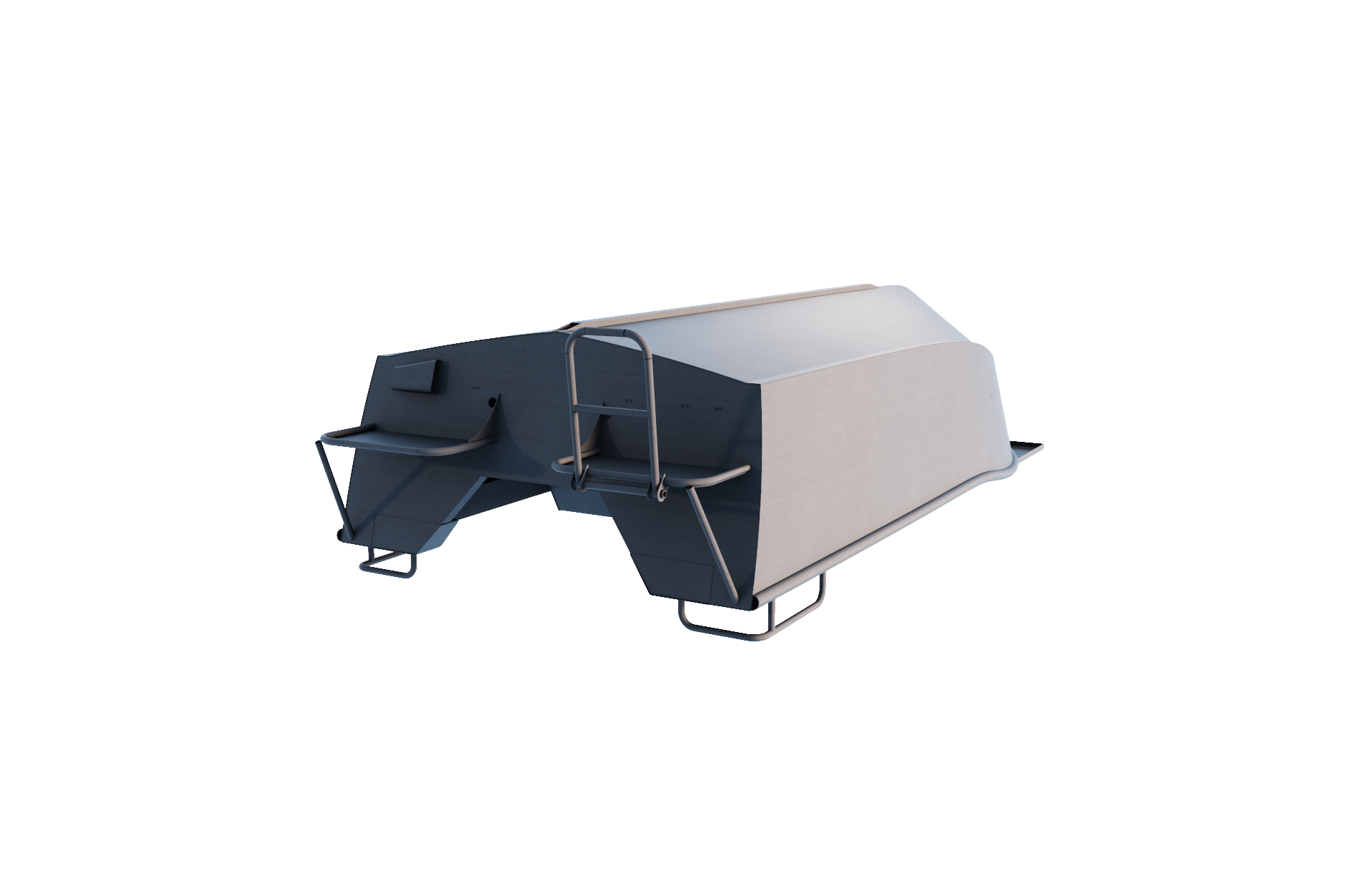

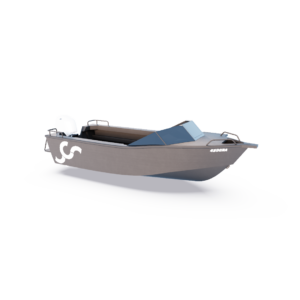

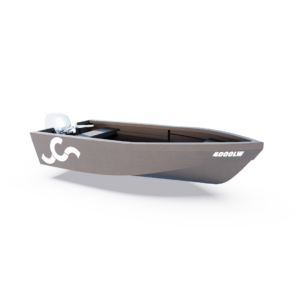

Thoughts and features

OPEN DECKS | TILLER STEER | SIDE CONSOLE

Get more information

Become a CNC Marine Member for FREE and gain access to general arrangements, typical sections and 3D viewers on all models.

After you sign up/in come back to any boat model and there will be links for more information displayed on the page.

Gallery

Some modifications or customisations – may not be representative of the final kit.